McClain Athletic Facility

Student athletes at the University of Wisconsin now practice under a Tensotherm™ insulated translucent membrane roof at the McClain Athletic Facility, where Birdair, Inc. served as the roofing contractor and provided design-build services for the roof retrofit.

Fabric Type: Insulated Tensioned Membrane

Market Sector: Stadiums / Arenas

Project Size: 41,920 sq.ft.

Architect: VOA Associates

Engineer: Berners Schober Associates

Owner: University of Wisconsin

General Contractor: Berners Schober Associates

Completion Date: September 12, 2012

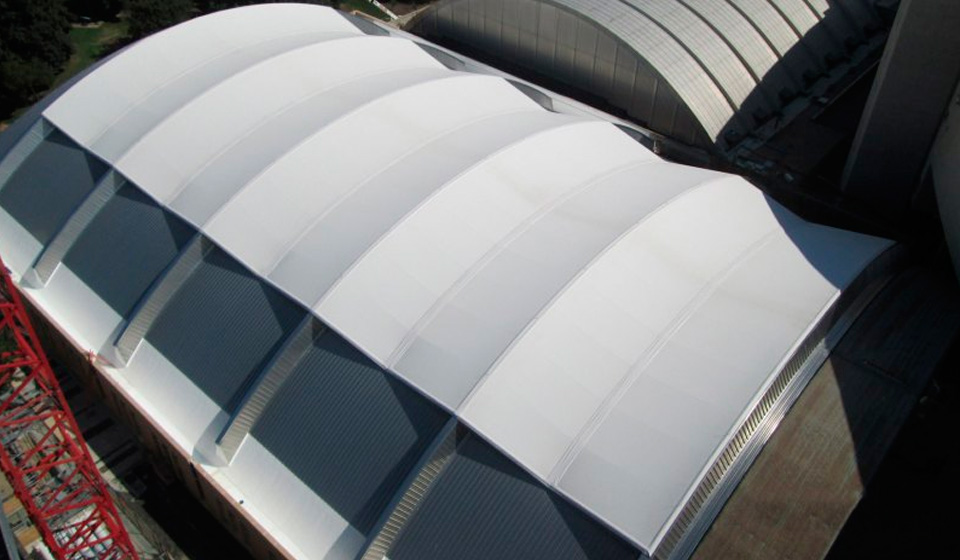

Student athletes at the University of Wisconsin now practice under a Tensotherm™ insulated translucent membrane roof at the McClain Athletic Facility in Madison, Wisconsin. As part of the university’s new $76.8 million “Athletic Village” development, the roof at the training facility was upgraded from non-insulated PTFE constructed by Birdair in 1988 to a new 41,920-squarefoot Tensotherm™ roof.

Birdair, Inc. served as the roofing contractor and provided design-build services for the roof retrofit. The new Tensotherm™ roof allows McClain Athletic Facility to maintain the look of its previous roof featuring tensile barrel vaults and standing seam metal roofing. On the interior, the roof’s existing structural support steel was cleaned for reuse and adds another element of aesthetic appeal.

Tensotherm™ with Lumira™ aerogel is an insulated translucent membrane roofing system developed by Birdair, Cabot Corporation and Geiger Engineers. For McClain Athletic Facility, the material consists of 25mm of Lumira™ aerogel insulation sandwiched between structural PTFE fabric, an insulated composite that is less than two inches thick (40mm), yet delivers an insulation value of R10.10. This innovative feather-light insulation layer reduces solar heat gain in warmer situations and retains warmer air in cold exterior conditions, which is key for Wisconsin’s climate.

“Before the installation crew stepped foot on the roof, Birdair had an excellent plan established,” says Jeremy Shecterle, P.E., LEED AP, AC, project executive for J.P. Cullen & Sons, Inc., the project’s construction manager. “The local craftsmen retained by Birdair learned the intricacies of the Tenostherm™ roof system to provide a safe and productive installation. Birdair worked closely with the standing seam roof contractor to assure the transitions and flashings were done properly to provide a watertight and continuous roofing system. The crew never wavered from the schedule and Birdair stayed on top of the project during construction. We would welcome the chance to work with Birdair again.”