Seymour Johnson Air Force Base Medical Clinic

Seymour Johnson Air Force Base Medical Clinic Aims High With Birdair

Fabric Type: Insulated Tensioned Membrane

Market Sector: Institutional

Project Size: 14,500 sq.ft.

Architect: Leo A. Daly Architecture

Engineer: Heery International

Owner: The U.S. Army Corps of Engineers

General Contractor: Heery International

Completion Date: January 21, 2016

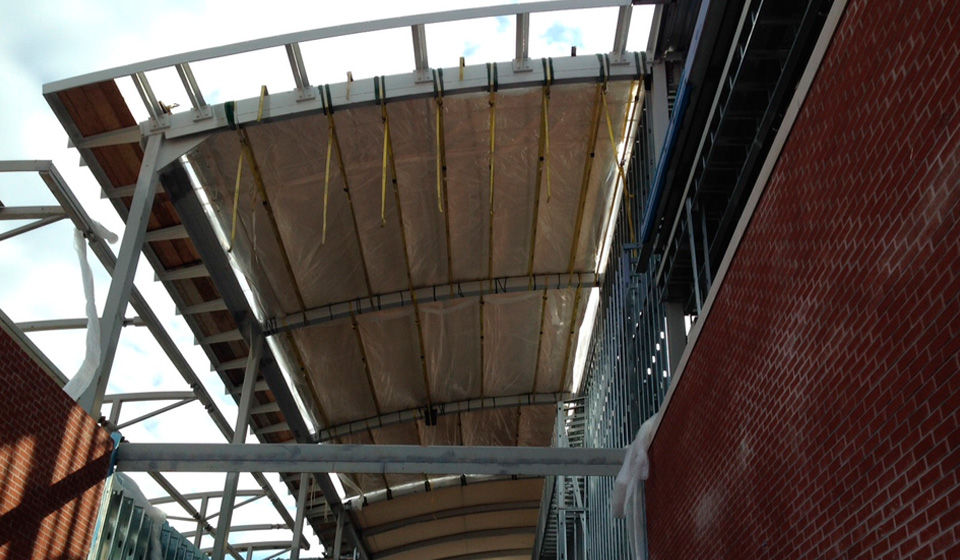

The U.S. Army Corps of Engineers and Heery International believe that a state-of-the-art medical center deserves state-of-the-art building products and that is why they tapped Birdair to design and construct the roofing system for the new Seymour Johnson Air Force Base Medical Clinic. Birdair will provide its revolutionary insulated tensioned membrane system that will serve as the 14,500 square foot roof of the new facility.

The medical clinic was originally designed by Leo A. Daly Architecture Firm. Heery International is working as the general contractor, architect and engineer on the project. Birdair's scope of work includes design, fabrication, supply and installation of the roofing system.

The Birdair roofing system features an insulated tensioned membrane composite system called Tensotherm™. Helping to achieve and enhance thermal performance, this system utilizes an 8mm translucent blanket of aerogel insulation, the world's lightest insulating solid. Not only does Tensotherm™ provide natural daylighting within the space below, but the insulation blanket also performs as an excellent dampener of sound.

Heery International selected Birdair for their design and installation expertise as well as for their unique insulated tensile fabric roofing material, Tensotherm™, which is the world's first and only translucent and insulated tensile fabric roofing material. It’s a composite material comprised of three components: PTFE fiberglass fabric membrane exterior skin; a translucent blanket, embedded with revolutionary Lumira™ aerogel thermal and acoustic insulation; and a PTFE fiberglass acoustic or vapor barrier interior liner.

Tensotherm™ offers superior thermal insulation and dampening of acoustics, but it’s also surprisingly lightweight. Comprised of 95 percent air, aerogel is the world's lightest solid material, making Cabot Corporation's Lumira® aerogel a perfect fit for lightweight PTFE fiberglass fabric membrane. Together, this combination of materials delivers a composite system that is lighter than any other insulated roofing option. The light weight eliminates the need for heavy supporting structures, minimizing material usage and cost, and reducing energy consumption for shipping and installation.